Some Known Details About Fan Clutches

Table of ContentsA Biased View of Fan Clutches10 Simple Techniques For Fan ClutchesThe Main Principles Of Fan Clutches

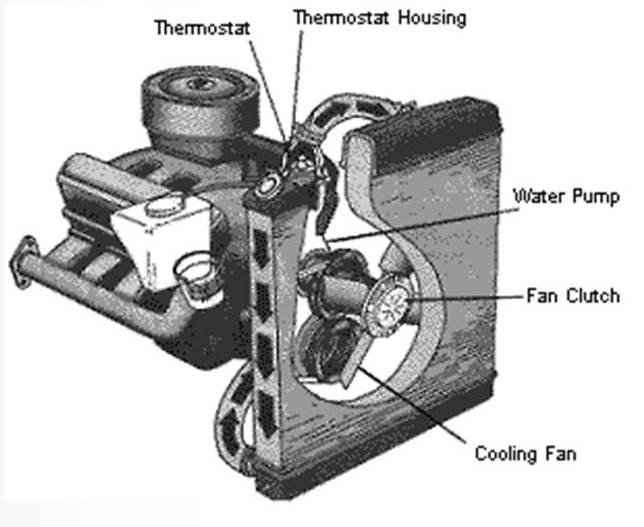

This develops friction in between the drive plate and the housing, causing the fan to spin. To disengage the fan, the valves close - fan clutches. The fluid is kept in the reservoir. This minimizes the friction and allows the housing and fan to spin independently of the shaft. This is where the clutch designs differ.

Non-Thermal Fan Clutches are rpm-dependent. Centrifugal force pushes the fluid versus the valves. At low rpm, the valves are open, allowing the fluid to stream and engaging the fan. As rpm increases, so does the centrifugal force. The force closes the valves and keeps the oil in the tank. This disengages the fan.

When the engine is cool, the fan is disengaged. As the temperature level increases, the spring rotates the valve plate and permits the fluid to circulation. This engages the fan. As the temperature level drops, the spring relaxes, rotating the valve plate back. This stops the fluid circulation and disengages the fan (fan clutches).

These clutches operate the exact same method as a thermal clutch. However, the valves are controlled by a signal from the car's computer system. KEEP IN MIND: A clutch fan is never ever completely disengaged. Even when disengaged, the fan will turn at 20-30% of the water pump speed. The finest type of fan clutch is the one created for your application.

For better cooling, you can upgrade from a non-thermal or basic duty clutch to a sturdy or serious task clutch. However, replacing a thermal clutch with a non-thermal clutch is never advised. An electronic clutch ought to only be changed with another quality electronic clutch.

Efficiency add-ons quickly push the power limits of engines beyond what stock cooling systems can manage. As a basic maker, we recognize these obstacles and have developed an option with our low profile, heavy duty thermal fan clutch, P/N 2947. Sitting at only 2. 7" tall, our boosted design maintains the performance of the original fan clutch in a much smaller sized package, offering space for that thicker radiator for your V8 restoration job.

X You will get regular email updates on specials, brand-new items and upkeep ideas for your Ram Turbo Diesel pickup. We value your personal privacy. Your details will not be shared with 3rd parties. You may unsubscribe at any time.

The Single Strategy To Use For Fan Clutches

Cooling systems on fleet cars get a great deal of attention nowadays. High-tech coolants are readily available from a broad variety of sources, and each claims to be the solution to whatever problem your engine is dealing with. Coolant analysis can assist fleets keep the appropriate chemical structure of the coolant. Click Here to Check out More In fact, according to some professionals, incorrect cooling system care might be the cause of about 40% of premature engine failures.

You might be overlooking a frequently neglected, however critical, part of the truck's cooling systemthe fan clutch. "The technology in the commercial truck industry as it relates to fan clutches is really mature," says Jim Benson, applications engineering manager at Borg Warner. "However, we're dealing with the find out awareness that not everyone understands fan clutches and how they run." In a nutshell, a diesel engine must operate within particular temperature specifications to be most fuel effective.

However, considering that 2007 when brand-new EPA emissions regulations started producing the unexpected effect of higher heat in the engine compartment, increased attention has been paid to the style and operations of the fan clutches offered at the OE level. "There are a range of issues fleets need to think about with fan clutches, but the main problem we're seeing today with the later model post- '07 engines is greater cycling of the fan drives and longer run times," discusses Tom Hujik, director of North American Aftermarket Field Sales for Horton, Inc.

Extreme heat is bad for all underhood components. Power guiding pumps, air compressors and alternators have all been affected by this increased heat. Fifteen years ago 5% run time was typical of a fan drive. Now, it's closer to 30% on-time and significantly higher for trade trucks. image source Cycling and on-time leads to use whether it is an on/off or variable speed fan drive." Hujik states another culprit under the hood with post- '07 engines is the extreme biking of the fan due to the air conditioning system requirements.

" Simply put, when the A/C system engages the fan to cool the condenser, it should be on a minimum of one minute, which offers adequate time to lower the head pressure in the system. Simple enough, except for one problem, Hujik added. "All the ECMs from the factories must be configured this waymany of them weren't.

That's a sure way to wear the lining out quicker." Hujik discusses that all of these problems challenged the makers to develop a more efficient solution. "So through all that, the concept came about that since we have greater on-times, why not have a low-speed to look after that type of demand?" he says.

This design likewise supplies fuel cost savings, minimized fan noise and increased belt life in these types of applications." This biking concern isn't exclusive to simply one manufacturer, according to our experts, but remains in truth a prevalent issue for all fleets. But while biking concerns are recognized throughout the industry, Borg-Warner's Benson says the rush to do something about them hasn't been universal.

Excitement About Fan Clutches

You'll get the same life if you do the service, but you also have to preserve it," Benson discusses. Along with increased life span, both of our experts agree that variable speed fan clutches provide a host of other benefits. "Demand for power under the hood has actually increased," acknowledges Hujik.